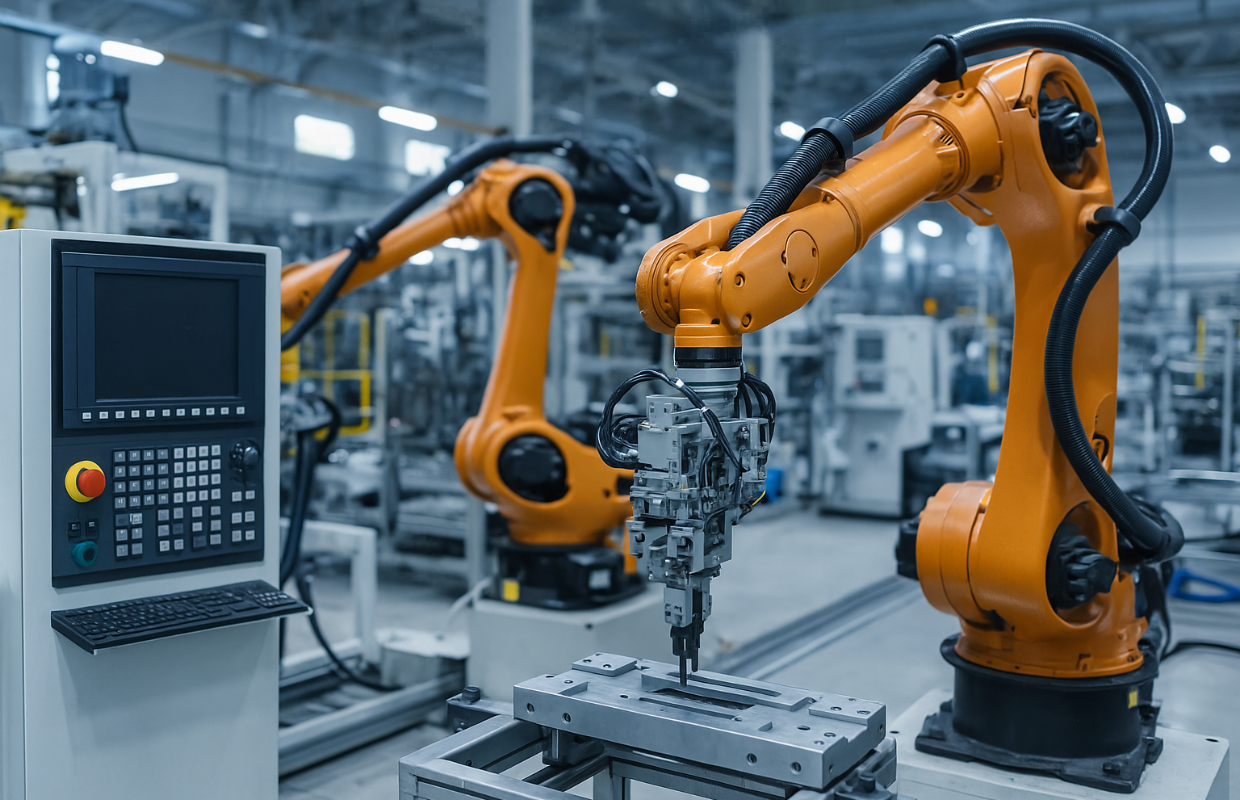

When you walk into a modern factory today, things look very different compared to a few decades ago. The machines take care of small tasks, robots work on putting pieces together, and computers keep track of the whole system. This is what we call manufacturing automation. For business owners and even for those who are just interested, it offers a clear advantage.

What Is Manufacturing Automation?

Manufacturing automation is when machines and computer systems take care of production tasks while people only guide them a little. Instead of people doing every single step, automated machines, robots, and software take care of repetitive or complex jobs.

Automation aims to:

- Improve efficiency

- Reduce errors

- Increase productivity

- Lower costs

In daily life, automation shows up in many places. Simple ones like vending machines and self-checkouts, or bigger ones like car assembly lines.

Types Of Manufacturing Automation

Not all automation looks the same. Here are the most common types you should know about:

1. Fixed Automation

It is used when the production process does not change much. Machines are programmed to follow fixed tasks. In car making, for instance, the same process keeps repeating.

2. Programmable Automation

Machines in this system can be reprogrammed for new work. It is useful when you make different products in turns. A machine might make one item this week and a new one next week.

3. Flexible Automation

This is the most advanced type. Machines can switch tasks quickly without needing long reprogramming. It helps factories change between products fast and smoothly.

Applications Of Manufacturing Automation

Automation is not tied to one sector. You will notice it in almost all areas of manufacturing. Here are some main applications:

Material Handling:

Automation is used in material handling, packaging, and shipping. Conveyor belts, robotic arms, and AGVs are common tools here.

Quality Control:

Automated systems inspect, measure, and test products very precisely. This cuts mistakes and makes customers satisfied.

Assembly Lines:

Robots and automated systems keep doing the same assembly tasks, making sure everything stays consistent and fast.

Welding & Painting:

Robots are commonly used in welding car parts or painting products. They guarantee precision, safety, and uniform results.

Inventory Management:

Software tracks stock instantly, making shortages and excess stock less likely.

Advantages Of Manufacturing Automation

You might wonder, why should a company invest in automation? The benefits are clear and long-term:

- Automated machines keep running without stopping. That makes production faster and hitting deadlines easier.

- The first investment might be large, but automation reduces labor expenses and waste. In the long run, companies save plenty.

- Because machines follow exact instructions, errors are reduced. This provides consistent and reliable quality.

- Dangerous jobs like lifting, welding, or dealing with chemicals can be done by machines. This helps keep workers safe and avoids accidents.

Are Humans Being Replaced By Automation?

A common fear is that automation will steal jobs. The reality is different. Machines handle repetitive tasks, but they also open new opportunities. People are needed to plan, program, and manage these systems. Workers can leave routine tasks and take on skilled roles. Automation helps humans focus on creativity, problem-solving, and innovation.

Why Manufacturing Automation Matters To You

Whether you are a business owner, an employee, or simply curious, automation matters to you. For businesses, it means growth and leading in the market. For staff, it means learning new skills to operate with technology. For you as a customer, it means better items, faster shipping, and usually at a lower price.

In Short

Manufacturing automation is more than a trend. It is changing industries all over the world. From production lines to stock management, automation brings speed, precision, and safety. It changes how we work and opens up new opportunities. If you run a business, it’s time to consider automation. Begin small, check the tools you have, and expand later.

If you want to learn how automation can transform your business, Groundup.ai is ready to help. Our experts can show you how to increase efficiency, reduce costs, and improve product quality while keeping your workforce safe and motivated. Don’t wait to embrace the future of manufacturing. Take the first step today, and let’s build smarter, faster, and safer operations together.