The best fix is the one you never have to make!

Predict. Prevent. Perform.

Reduce downtime and boost efficiency with intelligent, data-driven maintenance.

AI-powered insights to stop

downtime before it starts

Engineered to deliver AI-powered maintenance intelligence, wherever the cloud can't go

Engineered to deliver AI-powered

maintenance intelligence, wherever

the cloud can't go

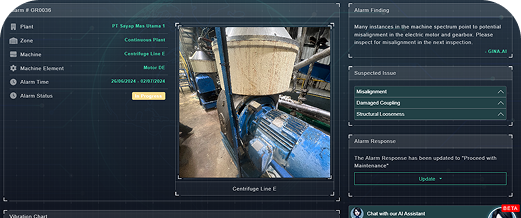

The Future is Cognitive: Stop reacting to equipment failures and start predicting them with Cognitive Maintenance,

powered by the world’s first agentic AI for industrial uptime.

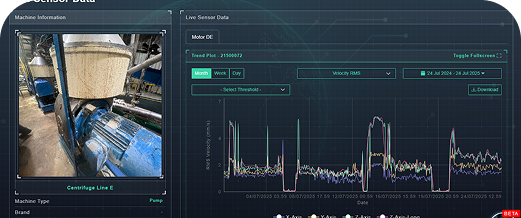

Install in minutes without modifying your machinery. Our magnetic IoT sensors capture vibration, sound, and temperature for high-precision monitoring.

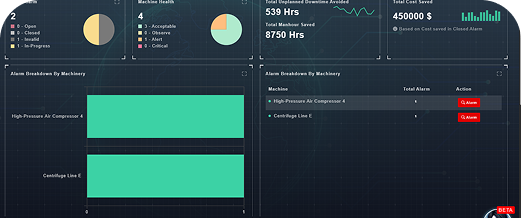

One unified view of your machine fleet with AI-

generated health scores that help your team prioritize instantly.

Spot early warning signs before they spiral into

breakdowns or safety hazards.

Go beyond alerts. Our AI suggests corrective actions with context, so your engineers act faster and

smarter.

30+ businesses in 5 countries rely on Groundup.ai to cut costs, scale operations, and eliminate unplanned downtime.

From Coca-Cola to The Republic of Singapore Navy, and across industries from Manufacturing to Maritime, Groundup.ai helps enterprises turn maintenance from a cost center into a strategic advantage.

Technical & Supply Chain Director, Coca-Cola Bottling Saudi Arabia

Lead Engineer

Cognitive Maintenance, Tailored to Your World

From deep-sea vessels to production floors, Groundup.ai powers smarter

maintenance across mission-critical industries.

Explore how global leaders in defense, aerospace, and manufacturing use our platform to automate maintenance, prevent failures, and maximize uptime.

We’re on a mission to help industrial companies predict the unpredictable.

As the Middle East and Asia’s leader in AI-powered Cognitive Maintenance, we combine deep tech with deep industry knowledge to help you solve real-world problems, before they become real-world disasters.

Latest Funding: US$4.25 million Series A Round Led

by Tin Men Capital

Expansion into Indonesia, Qatar, Saudi Arabia, and United Arab Emirates

Catch early warning signs before breakdowns happen with AI-powered anomaly detection.

Optimize maintenance workflows and resource usage with real-time insights.

Keep your machines running longer with predictive alerts and smart diagnostics.

Where the future of maintenance gets built, together. At Groundup.ai, we’re cultivating a community of forward-thinking engineers, technicians, and leaders who are shaping the future of maintenance with AI. Step into our tight-knit space for real-time conversations, peer advice, and early access to tools, tips, and events.

Uncover ideas and expert advice for smarter maintenance operations.

WhatsApp us