Artificial Intelligence That Powers Next-Generation Industrial Maintenance

The best fix is the one you never have to make!

CMMS Maintenance Solution

Streamline scheduling, tracking,

and compliance

Cognitive

Maintenance

AI-powered insights to stop

downtime before it starts

On-Premise

Engineered to deliver AI-powered maintenance intelligence, wherever the cloud can't go

On-Premise

Engineered to deliver AI-powered

maintenance intelligence, wherever

the cloud can't go

The World's First Agentic AI For

Cognitive Maintenance

The Future is Cognitive: Stop reacting to equipment failures and start predicting them with Cognitive Maintenance,

powered by the world’s first agentic AI for industrial uptime.

Non-Invasive Sensor Deployment

Install in minutes without modifying your machinery. Our magnetic IoT sensors capture vibration, sound, and temperature for high-precision monitoring.

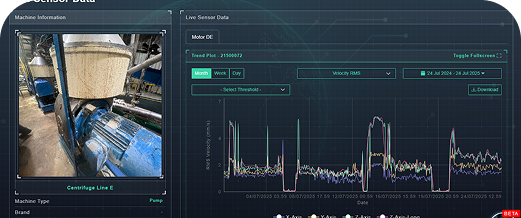

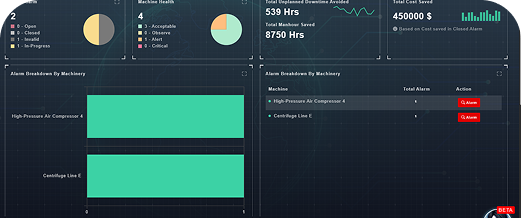

Real-Time Machine Health Dashboard

One unified view of your machine fleet with AI-

generated health scores that help your team prioritize instantly.

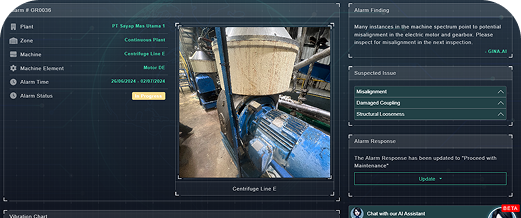

92% Accuracy in Anomaly Detection

Spot early warning signs before they spiral into

breakdowns or safety hazards.

AI-Powered Root Cause Analysis

Go beyond alerts. Our AI suggests corrective actions with context, so your engineers act faster and

smarter.

What We've Achieved

30+ businesses in 5 countries rely on Groundup.ai to cut costs, scale operations, and eliminate unplanned downtime.

Deep diagnostic insights across complex failure modes

Proven at scale across diverse industrial environments.

Helping teams stay ahead with smarter, uninterrupted operations

Built to adapt across a wide range of industrial equipment

Helping teams stay ahead with smarter, uninterrupted operations

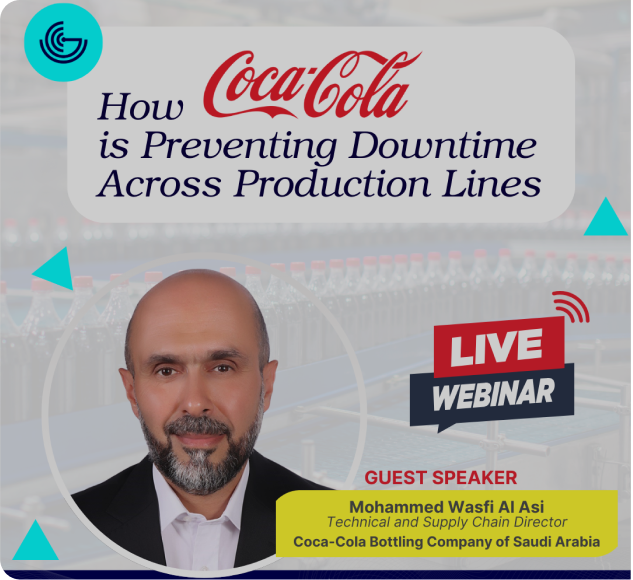

Trusted By Industry Maintenance Leaders

From Coca-Cola to The Republic of Singapore Navy, and across industries from Manufacturing to Maritime, Groundup.ai helps enterprises turn maintenance from a cost center into a strategic advantage.

Mohammed Wasfi

Technical & Supply Chain Director, Coca-Cola Bottling Saudi Arabia

Eugene Lee

Lead Engineer

Industries We Serve

Cognitive Maintenance, Tailored to Your World

From deep-sea vessels to production floors, Groundup.ai powers smarter

maintenance across mission-critical industries.

Real-Life Success Stories

Explore how global leaders in defense, aerospace, and manufacturing use our platform to automate maintenance, prevent failures, and maximize uptime.

Infrastructure & Facilities Management

Materials Manufacturing

Materials Manufacturing

Built For The Industrial World

Mission

We’re on a mission to help industrial companies predict the unpredictable.

Vision

As the Middle East and Asia’s leader in AI-powered Cognitive Maintenance, we combine deep tech with deep industry knowledge to help you solve real-world problems, before they become real-world disasters.

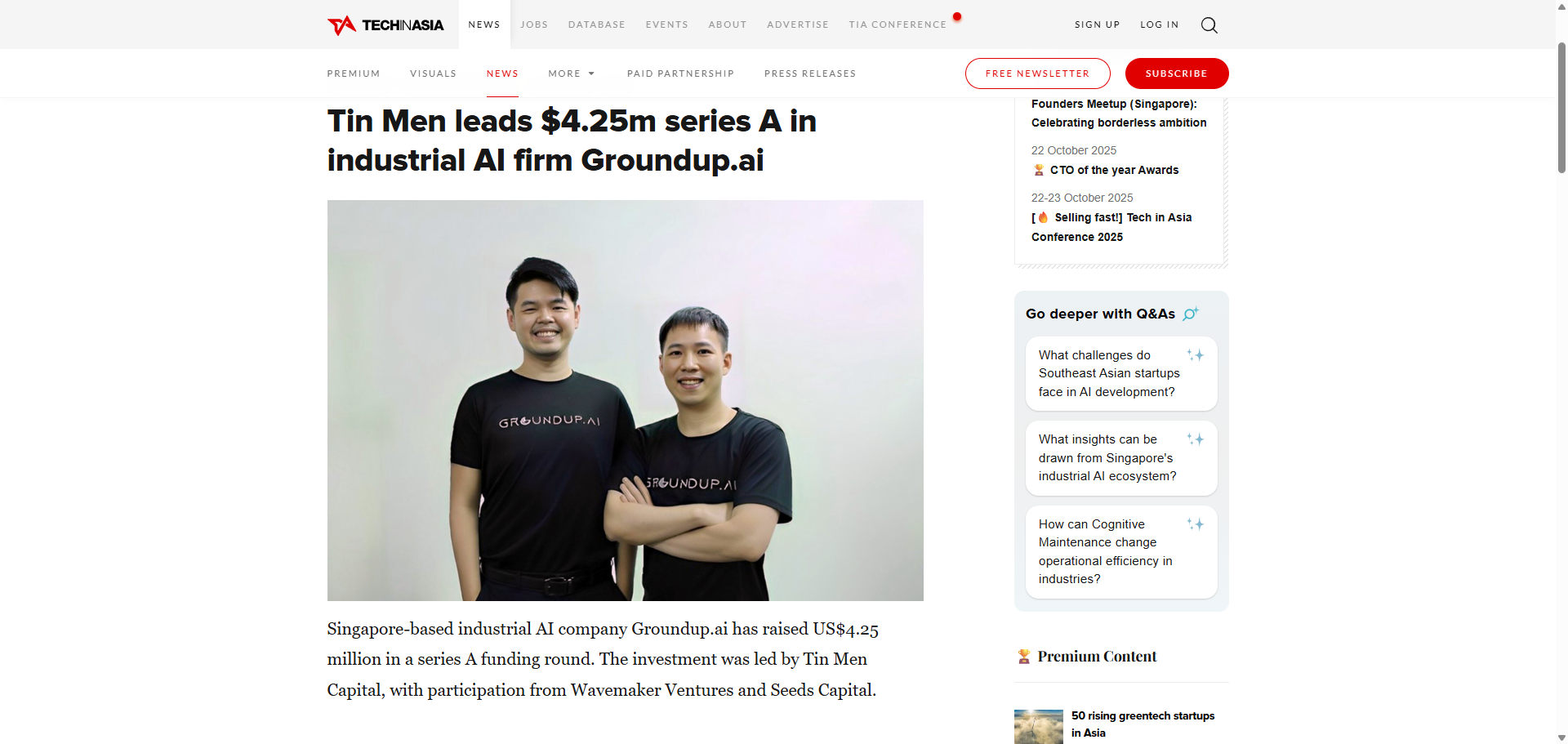

Built With Global Backing

Latest Funding: US$4.25 million Series A Round Led

by Tin Men Capital

Scaling Across Borders

Expansion into Indonesia, Qatar, Saudi Arabia, and United Arab Emirates

Let’s Get Started

Prevent failures

Catch early warning signs before breakdowns happen with AI-powered anomaly detection.

Drive efficiency

Optimize maintenance workflows and resource usage with real-time insights.

Increase uptime

Keep your machines running longer with predictive alerts and smart diagnostics.

Ready to

transform

transform your maintenance operations?

your maintenance operations?

Be part of our growing ecosystem

Join the Maintenance Maestros Community

Where the future of maintenance gets built, together. At Groundup.ai, we’re cultivating a community of forward-thinking engineers, technicians, and leaders who are shaping the future of maintenance with AI. Step into our tight-knit space for real-time conversations, peer advice, and early access to tools, tips, and events.

Groundup.ai Academy

Bite-sized lessons, playbooks, and video tutorials to help you master AI-powered Cognitive Maintenance, at your own pace.

Bite-sized lessons, playbooks, and video tutorials to help you master AI-powered Cognitive Maintenance, at your own pace.

Maintenance Maestros Podcast

Real voices from the field. Discover stories of innovation, challenges, and wins from unsung maintenance heroes across industries

Real voices from the field. Discover stories of innovation, challenges, and wins from unsung maintenance heroes across industries

Read our Blog: Shaping the Future of Maintenance

Uncover ideas and expert advice for smarter maintenance operations.