Predictive maintenance means checking machines before they break. It finds small problems early and fixes them. This way, the machine does not stop suddenly. For example, if a machine starts making a strange noise, that might mean something is wrong. Predictive maintenance listens to the machine and says, “Check this now before it becomes a big problem.”

What Is AI?

AI stands for Artificial Intelligence. This means smart computers that can learn, think, and make decisions like humans. AI looks at data and finds patterns. It can understand what is normal and what is not. AI is now used in phones, cars, and even factories. AI takes care of machines using data in factories.

What Is AI-Driven Predictive Maintenance?

AI-driven predictive maintenance means using smart computers to check machines, find small problems early, and tell workers what to fix. The AI watches machines all the time and learns how they work. If something starts to change like a part gets too hot, or a motor slows down then AI notices it. Then it sends a warning. This gives workers time to fix the machine before it stops working.

How Does It Work?

Let’s see how AI-driven predictive maintenance works in a factory.

1. Sensors Collect Data

Every machine has small tools called sensors. These sensors watch things like:

- Temperature

- Speed

- Vibration

- Noise

- Pressure

These sensors send data to the computer all the time.

2. AI Looks At The Data

The AI collects all this data and starts learning. It learns what is “normal” for each machine. For example, if a motor always runs at 100 RPM (speed), the AI remembers this.

If the motor starts running at 90 RPM, AI will notice that something is different.

3. AI Finds Patterns & Warnings

The AI looks for signs of problems. It sees patterns in the data. If something changes then it sends an alert.

For example, the machine may be shaking more than usual. That may mean a part is loose. The AI sends a message like:

“Check machine number 2. It may need repair.”

4. Workers Fix It Before It Breaks

The factory team gets the alert. They check the machine and fix the small problem. This way, the machine does not break completely, and work can continue.

Example In Real Life

Let’s say a factory has a machine that packs food. The machine has many moving parts. The sensors watch how the parts move and how hot they get. One day, the AI sees that a motor is getting hotter than usual. It sends a message to the manager: “Motor on the packing machine may overheat. Please check.” The worker checks the motor and finds the belt is too tight. They fix it in 15 minutes. This problem may have stopped the whole machine, and the factory may have lost 3 hours of work without AI.

Why Is AI So Good For Predictive Maintenance?

Here are some simple reasons why AI is very helpful:

- Always Watching: AI looks at machines 24/7. It never sleeps or gets tired.

- Very Fast: AI can look at thousands of data points in seconds.

- Learns Every Day: AI becomes smarter as it gets more data.

- Gives Early Warnings: It sends alerts before big problems happen.

- Helps Workers: It makes the job easier for maintenance teams.

Where Is This Used In Manufacturing?

AI-driven predictive maintenance is now used in many parts of factories, such as:

- Motors & Pumps

- Conveyor Belts

- Cooling Systems

- Drilling & Cutting Machines

- Robot Arms

These machines are very important. If they stop, the whole factory may stop. So AI helps keep them running smoothly.

Benefits For The Factory

Using AI for predictive maintenance brings many good things for factories:

- Less machine breakdowns

- More working hours

- Less repair costs

- Better safety for workers

- Longer life for machines

- Better planning and fewer surprises

What Is Needed To Start?

A factory needs:

- Machines with sensors

- Internet or a local network to send data

- AI software to look at the data

- A team that understands how to use the system

Once it is set up, the system works by itself and gets smarter over time.

Final Thoughts

AI is changing how factories take care of their machines. With AI-driven predictive maintenance, we don’t wait for machines to break. We fix them early. This helps factories save time and money. It also makes the workplace safer and more productive. AI watches machines, finds problems, and helps workers fix them before big trouble starts.

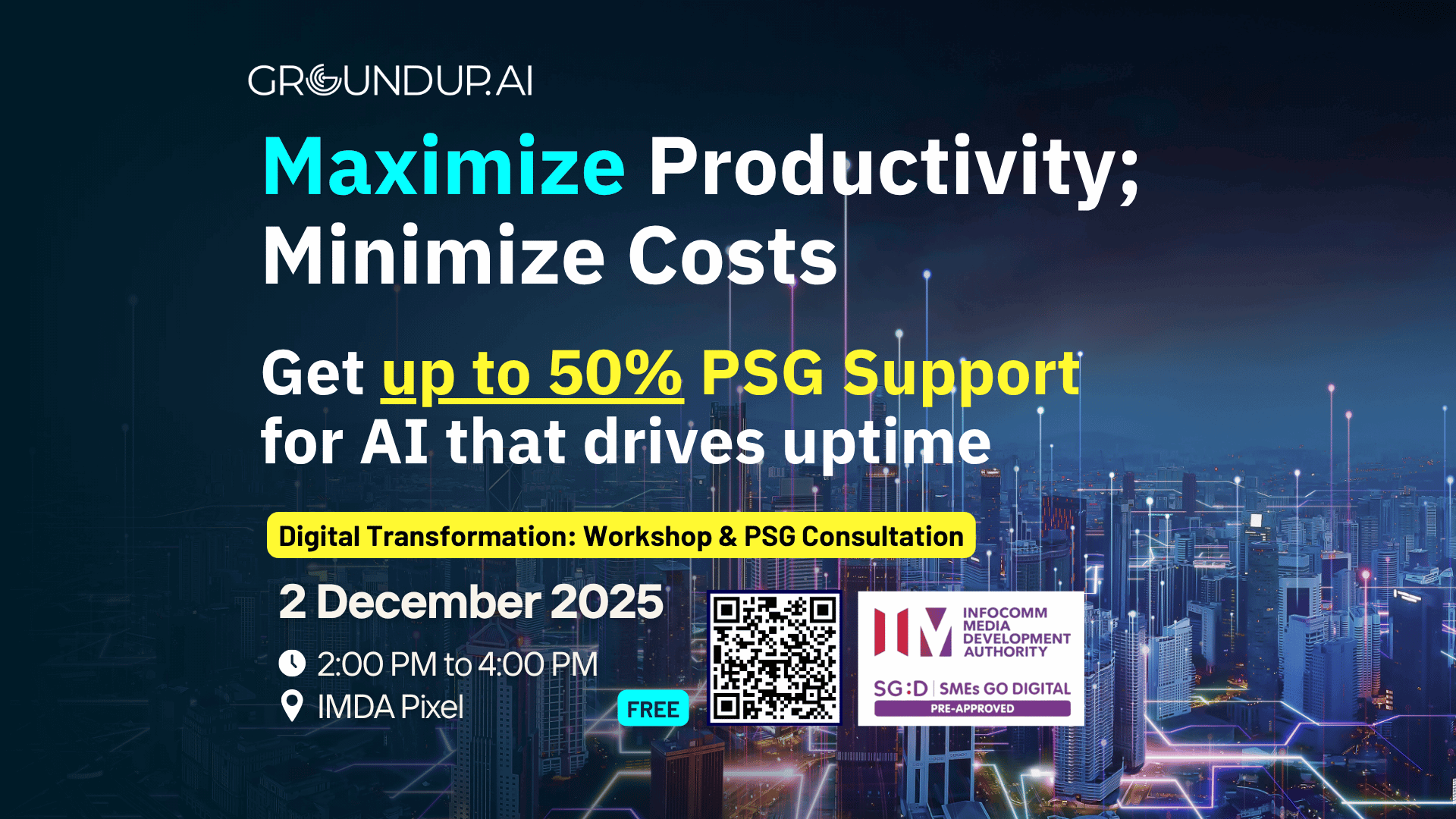

Here at groundup.ai, we have extensive expertise in the field of manufacturing. If you are interested in finding out how AI driven predictive maintenance can help you in manufacturing, feel free to Contact us!