In today’s fast-paced world, downtime is expensive. Every minute your machines are idle, your business could lose money. This is where AI comes in. AI-powered predictive maintenance is transforming industries. It helps stop failures before they happen and keeps your processes running well.

In this blog, you will discover what predictive maintenance is, how AI makes it smarter, and why your business should try it today.

What is Predictive Maintenance?

Predictive maintenance is a system that uses data and technology to estimate when equipment might stop working. Unlike regular maintenance, which happens on a schedule, predictive maintenance checks how your machines are actually doing.

With this approach, you can:

- Prevent equipment from breaking unexpectedly

- Save on maintenance costs

- Make machines last longer

- Ensure safety for workers

The key is knowing what your machines need before they fail.

How AI Powers Smart Maintenance

AI improves predictive maintenance. It can process huge amounts of data faster than any person. This gives accurate insights into the health of your machines. Here are some ways AI helps:

1. Data Collection & Analysis

Your machines generate lots of data each day. AI keeps collecting and checking this data. Sensors watch temperature, vibration, pressure, and other key signs. AI detects patterns that point to potential issues.

For example, if a motor is moving more than it should, AI can notice it before it breaks. That way, you can prevent costly problems.

2. Helping You Plan Maintenance

AI tells you the perfect time to service your machines. You don’t have to stick to a set schedule. Instead, you handle maintenance only when it’s needed.

This means:

- You save money on unnecessary repairs

- You don’t interrupt work unnecessarily

- Machines last longer

3. Keeping Everyone Safe

AI can notice problems that might be dangerous for workers. It can send alerts before an accident happens, helping your team stay safe and follow safety rules.

4. Spotting Problems Before They Happen

AI learns from the past. It looks at previous breakdowns and understands what warning signs to watch for. This way, you can fix issues before they cause big trouble.

It helps you:

- Fix machines only when needed

- Stop production delays

- Keep your business running smoothly

Real-World Examples

Many industries are already using AI-powered tools for maintenance with good results.

- Manufacturing: AI is used in factories to watch assembly lines. It stops machines from stopping unexpectedly and keeps things running smoothly.

- Transportation: Airlines and transport companies check vehicles and aircraft with AI. It stops delays and breakdowns, keeping things on track.

- Energy: AI helps power plants track turbines and generators. Predictive maintenance makes energy reliable and cuts repair costs.

With AI, these businesses save time, cut down costs, and run more efficiently.

How AI Makes Predictive Maintenance Better For Your Business

If you haven’t added AI to your maintenance approach, now is the time. Here’s why:

- Handling problems early cuts expenses.

- Your machines work longer, producing more.

- AI guides you to schedule repairs wisely.

- Companies with AI stay ahead with better efficiency.

Getting Started With AI In Predictive Maintenance

Implementing AI might sound complicated, but it doesn’t have to be. Start small by:

- Installing sensors on your critical equipment

- Collecting data on machine performance

- Using AI software to analyze the data and identify risks

- Acting on the AI insights to schedule maintenance

Over time, your predictive maintenance system will grow more accurate and stronger.

Errors You Don’t Want To Make

Even with AI, predictive maintenance works best when done correctly. Here are some mistakes to avoid:

- Ignoring Data Quality: AI is only as strong as the data it uses. Make sure sensors are functioning properly and collecting the right information.

- Waiting Too Long to Act: Don’t just look at AI alerts and ignore them. Acting quickly prevents small problems from becoming big ones.

- Trying to Do Everything at Once: Start with the machines that matter most. When you see results, you can bring AI to other equipment.

- Not Training Your Team: Make sure your team can read AI insights and know what to do next.

By avoiding these mistakes, you make sure AI works effectively and helps your business the most.

The Future Of Maintenance Is Here

AI changes maintenance from responding to problems to acting ahead of time. It helps your business operate efficiently. The technology is developing fast, and early adopters are seeing results. Don’t let your machines decide your business’s fate. Take control today with AI-powered predictive maintenance.

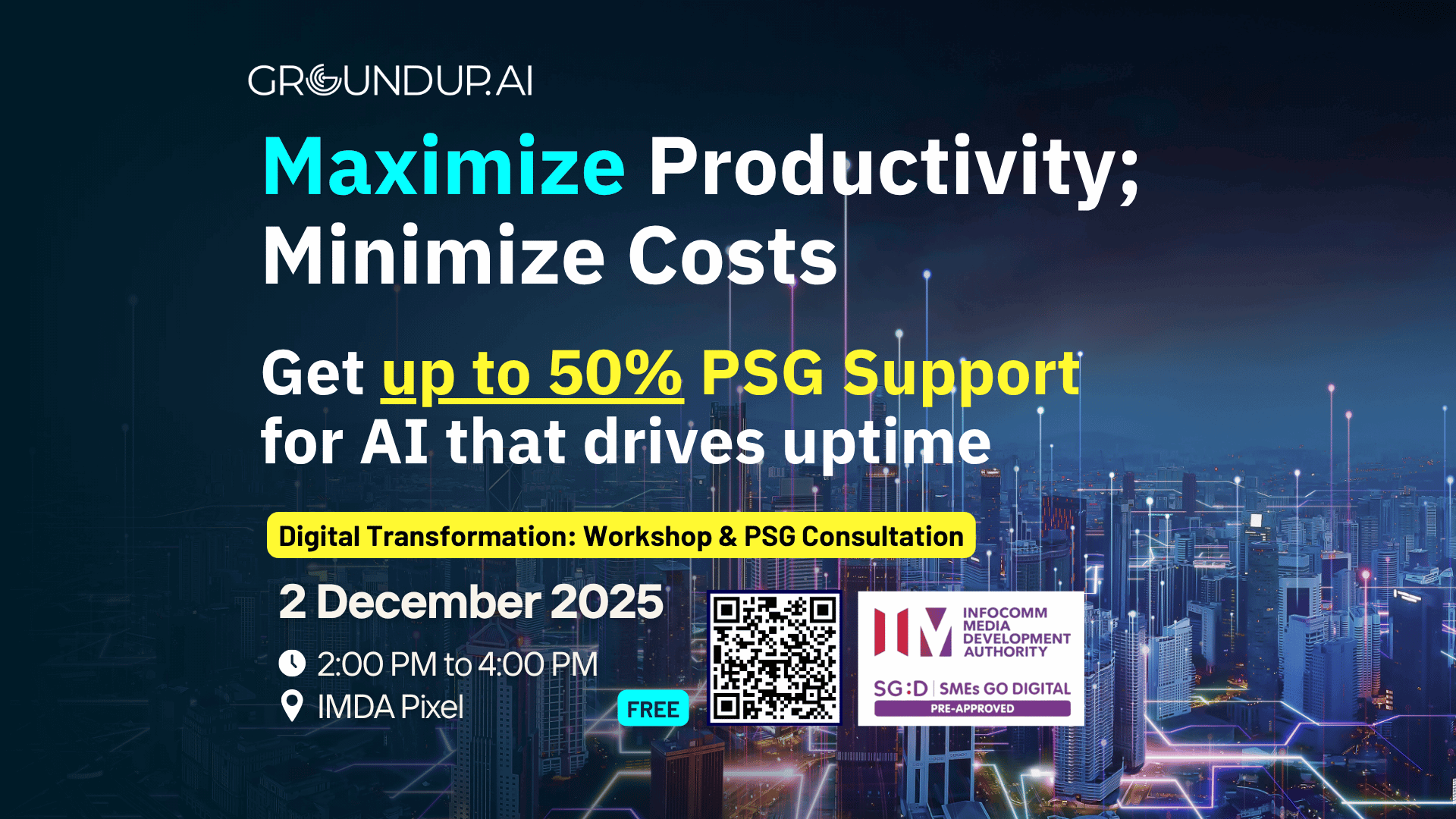

Want to upgrade your maintenance strategy? Check out Groundup.ai to learn how our AI solutions help avoid downtime, save money, and make operations better.