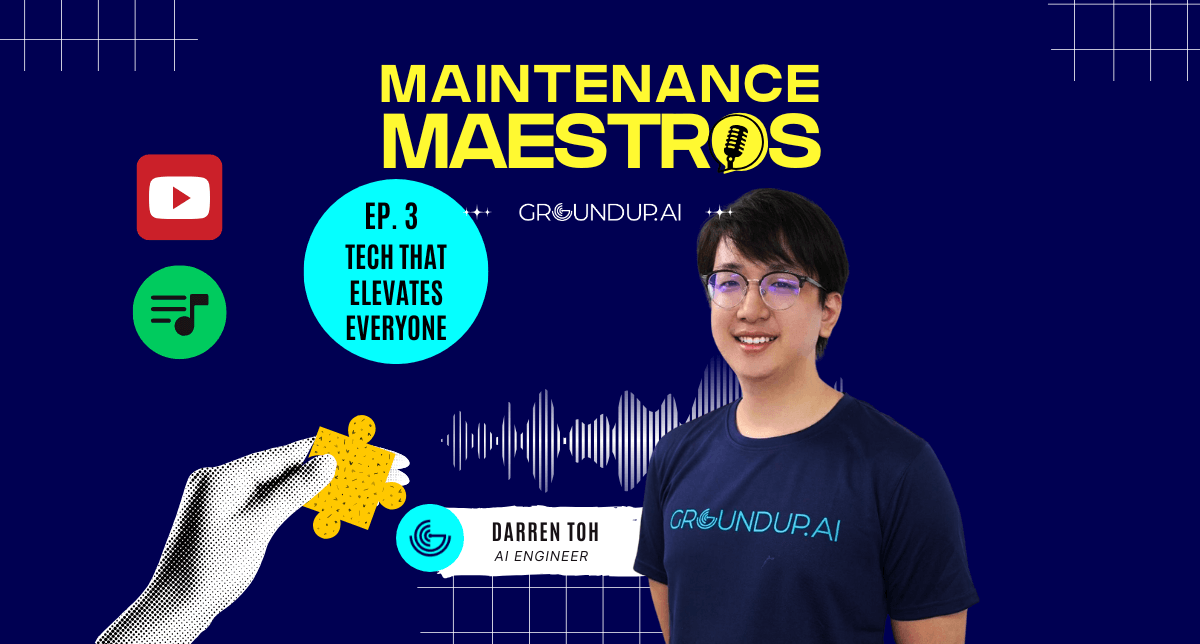

Maintenance Maestros Podcast – Season 1: Ep 3

Hosted by: Melissa Teo, Senior Marketing Manager, Groundup.ai

🎶 From Audio Engineering to Vibration Analysis

Darren brings a fascinating perspective to the field of Predictive Maintenance (PdM) because his initial career wasn’t in engineering at all. It was in music and audio engineering.

Darren discovered a surprising parallel between his past and his current work the moment he started looking at machine data. He realized that the charts and graphs used for vibration data, specifically the time domain and frequency domain spectrums, looked exactly like the software he used for audio engineering.

Why the similarity?

- Audio is simply vibration transmitted through air.

- Machine data is vibration transmitted through a physical medium.

The underlying principles of analyzing frequencies and their strength are identical. This connection perfectly illustrates how technology allows engineers to, in a way, listen to the machines first to understand what they are “thinking and feeling.”

Our talented AI Lead here at Groundup.ai is also a Mobius Institute Board of Certification Vibration Analysis VCAT II certified engineer!

Technology: Augmentation, Not Replacement

The common fear is that technology, particularly AI, is a threat meant to replace jobs. Darren counters that this is a short-term fear. Historically, technology has always led people to discover new and better ways to do things, dramatically increasing productivity.

I wouldn’t say that AI or tech is kind of replacing jobs. It’s actually just makes one person 10 to 100 times more productive.

In maintenance, technology scales the human element:

- Traditional Method: A plant engineer walks the ground, relying on intuition and routine.

- Technology & AI: When a factory scales, sensors and data allow that engineer to perform analysis at a macro level. AI automates the finding of patterns and trends, providing analytical insights that a plant manager needs to take proactive action.

Technology is augmenting, not replacing, the human element, it’s turning a single engineer into a strategic commander of multiple assets.

The Common Language: Bridging the Communication Gap

One of technology’s most powerful functions is serving as an efficient communication platform that connects intuition with facts. This common language solves a major headache in maintenance: the communication gap between operations and management.

Technology provides immediate context, replacing time-consuming reports:

- Visibility: Dashboards instantly communicate the status of every asset, making your work visible without constant manual reporting.

- Common Language: Everyone, from the ground staff to the C-suite, is speaking the same domain language because the terminology (e.g., “velocity RMS is exceeding a certain threshold”) is presented clearly and consistently on the dashboard.

- Efficiency: Management can quickly grasp the situation and make decisions, using data-backed facts to report further up the chain.

This shared understanding eliminates endless arguments over “gut feel” and fosters a more harmonious working relationship, leading to faster productivity.

Leveraging Tech for Career Advancement

For technicians looking to grow and for leaders seeking to hone talent, technology provides the concrete insights that translate to promotions and bigger roles:

1. Showcasing Critical Thinking

When all the raw data is provided on a dashboard, management doesn’t need a mouthpiece to repeat the facts. They are looking for someone who can provide critical insight.

An individual with ground experience who can connect data to operational reality stands out. For example, if a vibration spike appears, a technician can:

- Look at the data.

- Recall an operational change (e.g., “We put the system under a heavier load due to a temporary process change”).

- Advise management: “Not to be alarmed; let’s monitor until we return to the regular schedule.”

This ability to provide a strategic overview (backed by evidence) highlights critical thinking skills and shows they can see the bigger picture, making them ready for a larger scope of responsibility.

2. Quickly Adopting New Tools

The future of PDM talent lies in the ability to quickly adopt new AI features.

- Collaborating with AI: Older software was often rule-based. Newer AI systems learn from patterns and require user input. Technicians who are diligent in working with the tool, updating thresholds, and providing feedback will get more results out of it, making their program successful.

- Leveraging LLMs for Productivity: Tools based on Large Language Models (LLMs) can put all of a machine’s documentation (manuals, OEM guides) into a searchable interface. Junior engineers can query the AI to quickly ask: “If the shaft is having issues, what components of the system could affect it?” This instantly provides the relevant passages, allowing the technician to make a smart, targeted diagnosis without wasting hours reading manuals.

Just like a doctor uses AI to assist with diagnosis but makes the final judgment, the successful technician of the future will use technology as a powerful data point, but will never let go of the first principles and fundamentals of their job.

👉 See how Groundup.ai’s AI-driven dashboards help bridge the gap between engineers and executives with our Cognitive Maintenance solution.

In Summary:

- From Audio to AI – Vibration analysis and music production share the same principles of frequency analysis.

- AI as an Amplifier, Not a Replacement – Technology makes one engineer significantly more productive, scaling their expertise.

- The Common Language of Data – Dashboards build trust and efficiency by ensuring everyone speaks the same, data-backed language.

- Tech as a Career Accelerator – Use AI to showcase your critical thinking and adaptability to management.

▶️ Watch the series here: https://groundup.ai/podcast/